Four areas to consider when manipulating or repackaging commercial products.

Compounding has been part of the pharmacist’s role since time immemorial. It remains an important part of practice, allowing pharmacists to offer personalised medicines to patients. Compounding ranges from formulating with raw ingredients to reformulating commercial products. It may also be necessary for pharmacists to repackage commercial products to suit a patient’s needs.

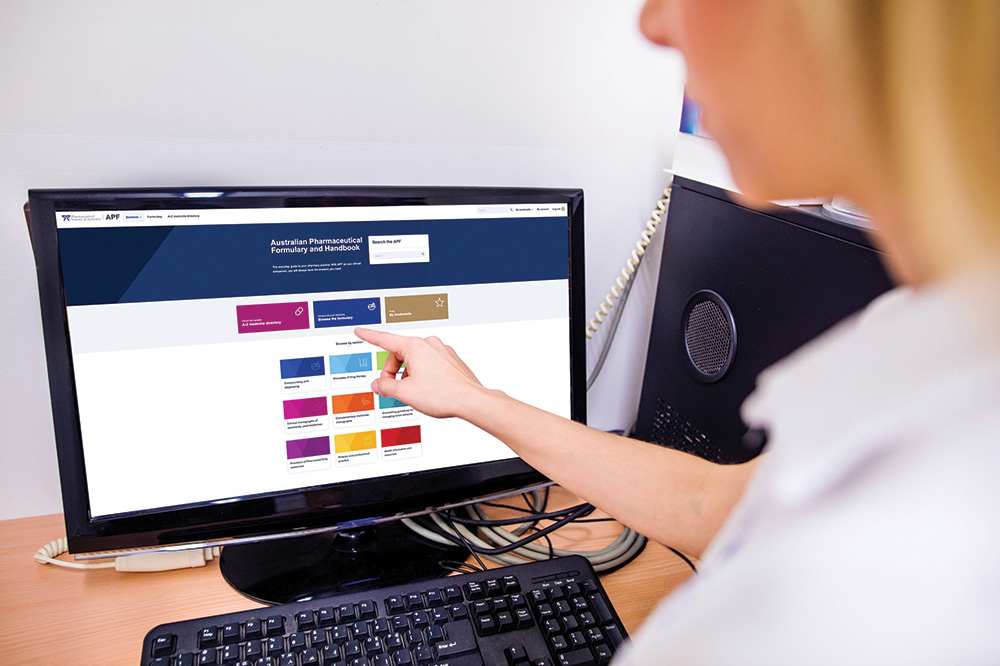

The Australian Pharmaceutical Formulary and Handbook (APF) is the primary reference for pharmacists extemporaneously preparing medicines. The most recent edition, APF26 print and updated APF digital, released in February, contains important updates to guidance on compounding formulations and on manipulating or repackaging commercial products. Some of these updates require a practice change, while other aspects of the guidance affirm expectations of practice that are not always upheld, usually inadvertently.

PSA Senior Professional Practice Pharmacist Carolyn Allen MPS says the changes ‘place a major emphasis on quality assurance processes and procedures’.

‘Revision of the APF compounding guidance has involved extensive stakeholder consultation in order to align the APF with other relevant compounding standards and guidelines wherever possible,’ she says. ‘This will provide pharmacists with consistent guidance across all areas of compounding practice.’

Here are four areas to consider.

1. How do you assign expiry dates for repackaged commercial products?

It may be necessary to remove a medicine from its original packaging to meet the needs of a patient, for example when packing a dose administration aid (DAA), or when preparing a staged supply.1

During this process, medicines can be affected by environmental factors, including light, heat and humidity. There is also the potential for physical contamination, such as by dust, skin flakes or pieces of packaging.

Before repackaging a medicine, pharmacists must complete a risk assessment to determine whether it is appropriate and supports the safe and effective use of the product.

The risk assessment should include (but is not limited to) assessing:

- suitability of the product for repackaging (e.g. stability, sterility, safety)

- suitability of the new packaging for the product (e.g. protection from light, moisture, contamination or leakage, container-closure integrity, child-resistance).

Removing a product from its original primary packaging invalidates the expiry date provided by the manufacturer, Ms Allen notes. The repackaged product must be labelled in accordance with legal and professional requirements, including an appropriate expiry date and storage conditions, and a number or code that links the repackaged product with the manufacturer’s batch number.

APF includes new tables with guidance, including recommended maximum expiry dates, for the repackaging of both non-sterile and sterile commercial products.

To determine an appropriate expiry date, pharmacists should consider ‘factors that influence the quality and stability of the product,’ according to the APF. This includes ‘the properties of the active ingredient and dosage form, the storage requirements for the product, the environmental conditions (e.g. heat, humidity, light) during repackaging and storage, and the risk of microbial and other contamination’.

To determine an appropriate expiry date, pharmacists should consider ‘factors that influence the quality and stability of the product,’ according to the APF. This includes ‘the properties of the active ingredient and dosage form, the storage requirements for the product, the environmental conditions (e.g. heat, humidity, light) during repackaging and storage, and the risk of microbial and other contamination’.

For example, APF specifies that a packed DAA should be assigned a maximum expiry of 8 weeks. In addition, the expiry should be no later than the manufacturer’s original expiry date of any individual medicine in the DAA and no later than the known period of stability of any individual medicine in the DAA (e.g. some brands of levothyroxine can be stored in a DAA for a maximum of 14 days below 25 °C). Medicines that are not stable when removed from the manufacturer’s primary packaging should not be repackaged (e.g. dabigatran capsules).2

2. Is flavouring oral mixtures compounding?

Adding flavourings to oral mixtures can make them more palatable, particularly for children. But, adding flavours to commercial products, if not in accordance with the manufacturer’s instructions, is considered compounding.

The APF chapter Good compounding practice sets out the quality assurance requirements that must be followed, including conducting a risk assessment, completing a compounding record

form and assigning an appropriate expiry date.

‘Pharmacists need to assure themselves that the flavour is a pharmaceutical grade ingredient and that it will not change the physical, chemical or microbiological stability of the existing formulation,’ Ms Allen says.

‘For example, citrus-based flavours, can change the pH of a formulation that requires a pH>8.’

3. Can you crush commercial tablets for compounding?

While the APF advises that it is usually preferable to use pure drug powder as the source of active ingredient, commercial products such as injections, tablets, capsules and creams are sometimes used as ingredients in compounded medicines.

‘This is a manipulation that is not in accordance with the manufacturer’s instructions,’ Ms Allen says. ‘That means this activity must meet the requirements of the APF Good compounding practice chapter.’

For example, when crushing commercial tablets to prepare an oral liquid, a compounding risk assessment must first be performed. The supplied formulation must be recorded in the patient’s medication record and endorsed on the prescription and duplicate (or the electronic prescription administration record). Pharmacists should also consider the impact that crushing a tablet might have on the efficacy of the medicine, for example enteric-coated tablets. ‘The enteric coating on a tablet dissolves in the intestine, rather than the stomach,’ Ms Allen says. ‘This is to prevent the active ingredient from being released into the stomach, where it could be unstable in stomach acid or damage the stomach lining.’ For example, proton pump inhibitors (PPIs) are acid labile, so PPI tablets are enteric coated, she explains.

‘Crushing tablets negates the enteric coating, and consequently the active ingredient may not be effective or may damage the stomach lining if made into an oral liquid.’

‘Crushing tablets negates the enteric coating, and consequently the active ingredient may not be effective or may damage the stomach lining if made into an oral liquid.’

4. Can eye drops be diluted?

Preparing eye drops is considered ‘complex’ compounding and must be done in a sterile environment with the right facilities.

APF includes a dedicated chapter on compounding sterile medicines, with guidance for pharmacists on how to comply with the principles of good manufacturing practice that apply to sterile compounding.

This is particularly important given there have been reports of pharmacists compounding eye drops without the appropriate facilities or equipment for preparing sterile medicines.3

‘Eye drops must be sterile,’ Ms Allen says. ‘The compounding, manipulation or repackaging of eye drops must meet the requirements of the new APF Compounding sterile medicines chapter, to reduce the risk of microbial contamination. For example, diluting eye drops should be performed in a laminar flow cabinet, pharmaceutical isolator or equivalent device with Grade A (ISO class 5) air quality.

‘The compounder must wear appropriate sterile garb and use a validated aseptic technique,’ she says. ‘In addition, the diluent used must maintain the quality, safety and efficacy of the eye drop. An expiry date and in-use expiry should be assigned in accordance with APF expiry date guidance.’

Top tips for the safe and effective manipulation of commercial productsCompiled by Claire Antrobus MPS, PSA’s Manager – Practice Support

4. If the manipulation is not considered to be compounding:

|

References

- Sansom LN, ed. Australian pharmaceutical formulary and handbook. 2024. At: https://apf.psa.org.au

- Product information. eMIMS plus.

- Pharmacy Council of New South Wales. Complaints to Council – compounding of eye drops. 2021. At: www.pharmacycouncil.nsw.gov.au/complaints-council-compounding-eye-drops

Professor Stephen Nicholls[/caption]

Professor Stephen Nicholls[/caption]

From centre: PSA SA/NT President Manya Angley FPS, Matthew Gillespie and Minister for Health and Wellbeing Chris Picton MP[/caption]

From centre: PSA SA/NT President Manya Angley FPS, Matthew Gillespie and Minister for Health and Wellbeing Chris Picton MP[/caption]

Pooja Jadeja MPS[/caption]

Pooja Jadeja MPS[/caption]